Tool Making(Die)

Tools for Die Components (Customizable)

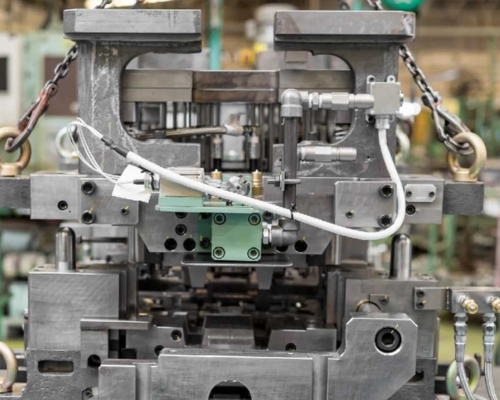

Tool making (Die)

Alucast Foundry specializes in manufacturing high-quality tools based on dies for aluminum casting components. These tools include machining fixtures, trimming dies, and inspection gauges, all precisely designed to match the geometry of the casting die. By developing these tools, Alucast ensures consistency in production, improves machining accuracy, and enhances the overall efficiency of the manufacturing process. The tools are carefully crafted using advanced CNC machining and heat treatment processes to achieve durability and precision.

The tooling process at Alucast Foundry begins with die analysis and 3D modeling to design custom tools that fit the specific component requirements. These tools are then manufactured from high-strength materials to withstand repeated use in machining and finishing operations. Properly designed tools help in achieving tight tolerances, reducing defects, and optimizing cycle times in aluminum gravity die casting. By integrating toolmaking with die development, Alucast ensures high-quality components with superior mechanical properties, meeting industry standards for automotive, aerospace, and industrial applications.

Resources

Infrastructures

MELTING FURNACE

We have two furnaces that can both melt and hold aluminum for casting. One furnace has a capacity of 250 kilograms, while the other can hold 350 kilograms. These furnaces help in maintaining a steady supply of molten aluminum for production. The melting process ensures that the aluminum reaches the right temperature for casting. Once melted, the metal stays in the furnace at a controlled temperature. This prevents it from cooling down too quickly before being poured into molds. The furnaces improve efficiency by reducing the need for frequent reheating. With these, we can produce high-quality aluminum castings consistently.

CASTING POURING AREA

The casting pouring area in Alucast Foundry is a critical zone where molten aluminum is carefully transferred into pre-heated molds to form high-quality gravity die cast components. This area is designed to maintain strict temperature control to ensure uniform filling of the die cavity, minimizing defects like porosity and cold shuts. Operators follow precise pouring techniques to achieve consistent metal flow, reducing turbulence and ensuring optimal material properties. Safety is a top priority, with protective gear and controlled environments to prevent accidents from molten metal handling. The pouring ladles are regularly maintained to avoid contamination and ensure smooth pouring operations.

CUTTING AREA

The cutting area is equipped with a large bandsaw cutting machine, capable of cutting castings up to 2.5 feet in width. This high-capacity machine ensures precise and efficient cutting, minimizing material waste and improving productivity. It is designed to handle heavy-duty aluminum castings with smooth and accurate separation of excess material. The robust blade system allows for consistent performance, reducing manual labor and improving workflow. Safety features such as operator shielding and controlled cutting speed ensure a secure working environment. This cutting setup plays a vital role in preparing castings for further machining and finishing processes.

FETTLING AREA

The fettling area is equipped with a belt grinding machine and multiple angle grinders for efficient casting fettling. The belt grinding machine ensures smooth surface finishing by removing excess material and sharp edges from the castings. Angle grinders provide flexibility for detailed fettling, allowing operators to reach complex areas with precision. These machines help improve productivity by reducing manual effort and enhancing the quality of finished components. Safety measures, including protective gear and dust extraction systems, ensure a secure working environment. This setup plays a crucial role in refining cast components before further processing.

Get Quote

Address

346/1a, Gandhi Nagar, Irugur post, Coimbatore – 641103

Call Us

+91 73732 06622

Email Us

sales@alucastfoundry.com